What is the replacement cycle and how to maintain the oil filter element? The editor of Xinyuan Environmental Protection will provide a detailed explanation. Xinyuan Environmental Protection Technology produces various types of oil filter elements, with complete models and affordable prices. The filter element is the working medium for the purification system, and the filter element is usually the main component installed in the filter or oil filter. Used to filter out pollutants generated by the wear and tear of various components in the system, ensuring the safe and efficient operation of the system.

When the filter element of the oil filter is working, the contaminated oil enters the heater through the inlet under the action of external atmospheric pressure vacuum suction. The heated oil enters the primary filter, and large particulate impurities are filtered out. Then, the oil enters the water separator, vacuum separator, and flows through a specially designed divergence device. This divergent device generates a huge surface area per unit volume of oil, exposing contaminated oil to a vacuum with low relative humidity, thereby removing water, air, and gases from the oil. The mixture of evaporated water vapor and gas is condensed into a liquid through a water tank and a cooler, which enters the water reservoir together. The remaining gas is extracted by a vacuum pump. The oil that removes moisture is fed into the fine filter by the oil discharge pump to remove particulate impurities, which is called purified oil. A purification process is completed, and depending on the water content, multiple cycles are required to completely remove moisture.

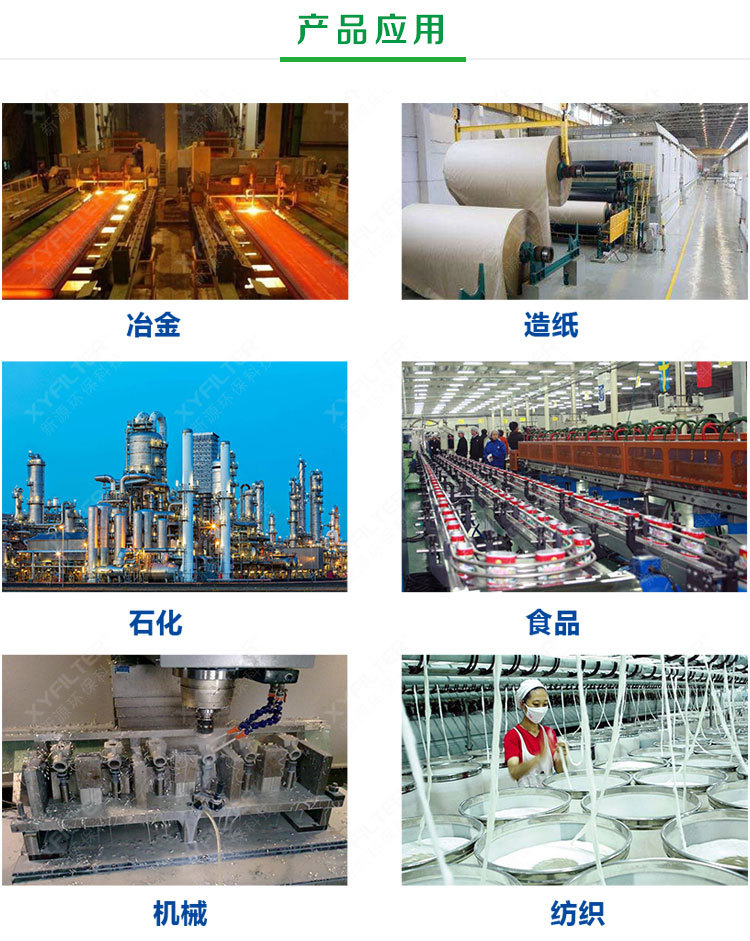

The hydraulic oil filter has a wide range of applications and is suitable for purification and regeneration of various lubricants in industries such as petroleum, chemical, mining, metallurgy, power, transportation, mechanical manufacturing, railway, etc. It has significant economic benefits.

After using the machine for a period of time, the oil will be changed. Although the new oil and the old oil should be of the same brand and specification, before changing the oil, all the old oil should be drained and rinsed thoroughly. Places such as the valve body and hydraulic cylinder that cannot be drained or rinsed should be cleaned, as mixing the new and old oil can affect the quality of the hydraulic oil.

1. Air. If there is gas in the hydraulic oil circuit, when bubbles overflow, they will impact the pipe wall and components to form cavitation, making the system unable to work properly, and even causing component damage if the time is slightly longer.

2. Oxidation. The working temperature of hydraulic oil in general construction machinery is 30-80 ℃, and the lifespan of hydraulic oil is closely related to its working temperature. Experience tells us that when the working oil temperature exceeds 60 ℃, for every 8 ℃ increase, the lifespan of the oil will be halved, that is, the lifespan of 90 ℃ oil is about 10% of that of 60 ℃ oil, because the oil is oxidized.

3. Water. The water content in the oil shall comply with the technical standards of GB/T1118.1-94, and after testing, its quality index shall not exceed the mark. If the water content in the oil exceeds the standard, it must be replaced; Otherwise, not only will it damage the bearings, but it will also cause rust on the surface of the steel parts, which can emulsify, deteriorate, and generate sediment in the hydraulic oil, hinder the heat conduction of the cooler, affect the operation of the valve, reduce the effective working area of the oil filter, and increase the wear and tear effect of the oil. Therefore, it is important to choose good hydraulic oil.

4. Physical and chemical reactions. Cleaning the paint inside the fuel tank can cause changes in the chemical properties of the oil.

5. Impurities. Impurities can not only wear out various moving parts, but once they are stuck in the valve core or other moving pairs, it will affect the normal operation of the entire system and cause machine malfunctions.

1. When not in use during car washing or machine operation, the fuel tank should be covered to prevent moisture from entering the air

2. Regularly filter hydraulic oil. Control the impurity particles in the oil within the specified range.

3. Before starting the machine, check the oil level and ensure that each oil circuit is in the correct standby state.

4. Run the machine at idle speed for about 5 minutes and check if there are any bubbles in the oil level gauge. If it is a new car or a new hydraulic oil, it is normal for bubbles to appear in the oil gauge during idle speed. Only after the bubbles disappear can the machine be allowed to operate.

5. Attention should be paid to whether the various parameter values of the hydraulic system are normal, and attention should also be paid to the external characteristics of the system - sound. If there is air intake, water, or poor oil circuit in the system, it will emit abnormal noise. At the same time, if the reading fluctuation display value of the instrument is abnormal, it should be stopped and checked in a timely manner.

6. Pay close attention to the temperature of the oil. After the machine has been working for a period of time, if the oil temperature is too high, it is best to stop and rest. After the oil temperature is normal, it can be restarted to extend the service life of the system and oil.

Contact: LEO

Phone: +86 13643907982

Tel: +86 373 3809023

Email: xy@xyfilters.com

Add: A11, 1st Floor, Chuangye Building, No.1 Park, High tech Zone, Xinxiang City, Henan Province